SUNRISE ALS | Automatic Angle Processing System

SUNRISE ALS

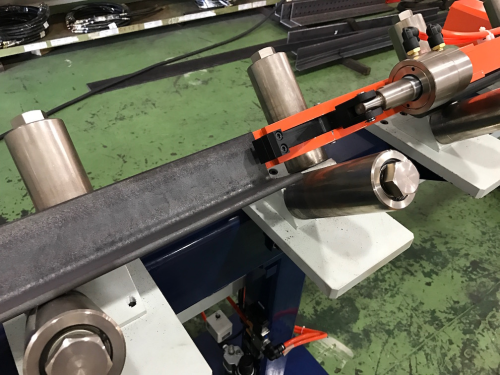

The SUNRISE ALS is a fully automatic angle processing system with the option to process flat-bar as well. The operator loads the angle onto the all-steel in-feed rollers, the system engages the material with pneumatic clamping and squaring devices and then processes the material by automatically punching both legs of the angle and shearing to length utilizing the industrial strength rack and pinion drive system.

Shearing Capacity:

Angle: 2″ x 2″ x 1/4″ up to 6″ x 6″ x 1/2″ – No Slug Loss

Optional Flat Bar: 2″ x 1/4″ up to 6″ x 1/2″ – No Slug Loss

Punch Capacity Per Leg:

1.5″ dia.up to the rated tonnage Material – 65,000 PSI Tensile.

Optional: Dual 1.5″ dia. punches per leg.

Positioning Speed:

Up to 40′ per Minute – Variable Speed

Accuracy:

+/- 0.006″/ Foot

Controller:

NEXCOM PC – 15″ Touch-Screen Controller featuring multi-program memory, nesting ability, multiple pattern templates, DXF Import, TeamViewer Remote Diagnostic, WiFi, USB

Standard Features:

– 20′ In-Feed with Rack-and-Pinion Drive System, expandable up to 40′

– Hydraulic Punch Stripper; Hydraulic Hold-down for shearing. Pneumatic hold-downs for in-feed.

– Dual Punch Feature – Allows one punch, up to 1.5″ capacity, per leg of angle.

– No slug loss shear cut featuring multi-sided blades.

– Quick Punch and Die Change – Average Tooling Cost $80/Set

– Automatic Pneumatic Material Clamping and Squaring

– Fully enclosed punching and shearing operations for operator safety including interlocked access doors to provide ability to change punch and die, access hydraulic and electrical components and more. – Integrated cooling system with hydraulic oil cooler.

Optional Features:

– Stamping/Marking Station

– Light Curtain Safety System

– Additional punch per leg, for a total of 4 punches.

– Automatic lubrication system with programmable spray pattern.

– Auto-Loader for Angles.

8_500x500.jpg)